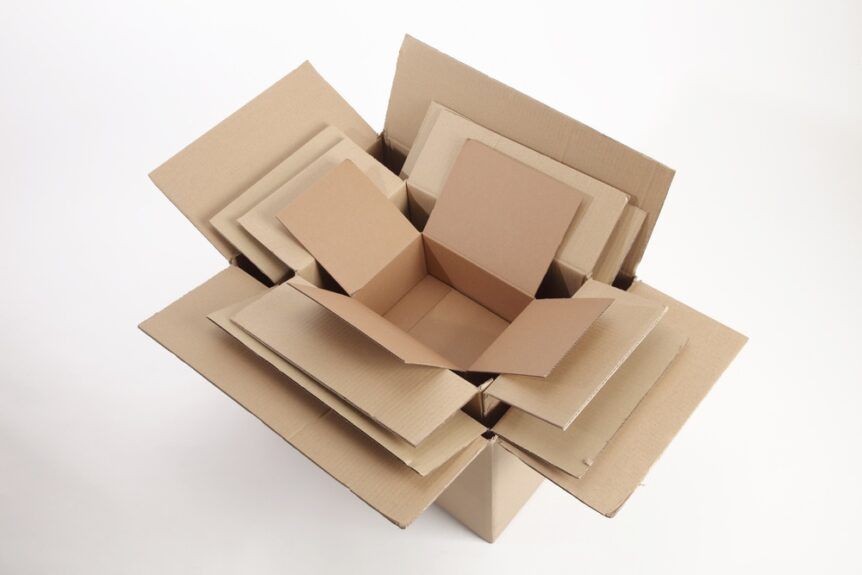

How much do you spend each year on sending empty boxes to your customers?

If you don’t control the size and shape of your outgoing packages, you may be spending more than you think. Package dimensions play both a direct and indirect role in the total cost of shipping, so if you have a lot of empty space inside your packages, you’re potentially paying for that space too.

So, in effect, you might be paying to ship nothing but air to your customers. And that’s not all – there are several other ways in which you could also be losing out.

Problems with bad packaging

Sustainable packaging can sometimes be something of an afterthought in the logistics process.

Of course, every detail in the shipping process matters. Poor packaging choices can have a number of consequences, such as:

DIM Costs

Since 2014, shipping firms have been following a dimensional pricing model, known as DIM. Under DIM, shipping firms calculate a price based on weight and another price based on size, and they will charge whichever is greater. It means that if your package is bigger than it needs to be, there’s a chance that you are incurring unnecessary shipping charges.

Environmental Cost

Even with the use of sustainable packaging, there is still an environmental impact to consider when putting together larger-than-necessary packages. On top of that, it causes more vehicles to be required on the road, as you can’t load as many packages onto a single truck or plane. All of this adds to your ecological footprint as a company.

Are you ready to amp up your shipping logistics?

Request a Quote from Pegasus’ Logistic Experts Now

Advantages of Optimal Packaging

Obviously, there’s a pressing business need to improve this part of your logistics process. Optimal packaging is the simple solution to all of these issues. This approach to packaging means providing your people with a broader range of tools for dealing with packaging tasks and empowering them to reduce the size of packages as much as possible.

There are numerous advantages of this approach:

Control Over Shipping Costs

DIM costs can be unpredictable. While you can make precise estimates of weight-based shipping costs, it’s impossible to be sure of size-based costs when you don’t have control over the sustainable packaging being used. With optimal packaging, you know how much it will cost to ship each order before it’s even processed. This means you forecast shipping costs with a much greater degree of accuracy and make better decisions about how to charge customers for shipping.

Environmental Responsibility

Throughout the whole shipping process, smaller packages made with sustainable packaging reduce your ecological impact by reducing waste and lowering the amount of fuel required to ship each item. From a corporate responsibility point of view, that’s a big step towards meeting your environmental obligations. It may also have other effects, from avoiding green taxes in certain territories to winning business from green-minded customers.

Benefits Cascade Through the Supply Chain

Predictability is a vital element in the supply chain. Manufacturers, distributors, retailers, logistics partners and transportation providers – all parties can work better together if they know every detail in advance, including the size of each package and the cost of shipping it. Optimal packaging introduces this kind of clarity throughout the process, which enhances cooperation among everyone involved.

Issues to consider with better packaging processes

The benefits of an optimized sustainable packaging system are obvious, but how do you go about implementing it? Logistics is a complex business and even relatively minor can have major implications for your organization and your people.

When making any changes to how you package outgoing goods, there are a few things you have to think about, such as:

Item Safety

The most important consideration in packaging is the safety of the item being transported. It’s something that you can’t take risks on. When items arrive in poor condition, not only do you face a bill for replacement, but you could potentially lose future business from the recipient. The key is to find a balance between ensuring the safety of the item in transit and keeping the packaging size to a minimum.

Managing Box Sizes

Optimal packaging means having a greater variety of box sizes available to packers so that they can choose the most suitable one. They may also need to adjust box sizes on the go or make other changes to optimize each package. This can require a reorganization in the packing area so that boxes are organized correctly and available where needed, and each person needs the proper tools to do their job.

Ideally, you should work with a logistics partner such as Pegasus who can provide an optimal packaging solution with all of the benefits and none of the risks.

In a world of tight margins and tough competition, it’s unacceptable to incur high delivery costs for no good reason. It’s even worse if the problem is just because you haven’t got the right packaging available for your warehouse staff. This is something that can and must be addressed immediately. Not only for your benefit, but for the good of the environment, to improve co-operation on your supply chain, and to make for a better experience for your customers.

Do you have any advice for sustainable packaging for fellow readers? What’s the best use of sustainable packaging you’ve ever seen? Let us know in the comments below and don’t forget to contact Pegasus and request a quote for an optimal packaging solution.

Are you ready to amp up your shipping logistics?

Request a Quote from Pegasus’ Logistic Experts Now