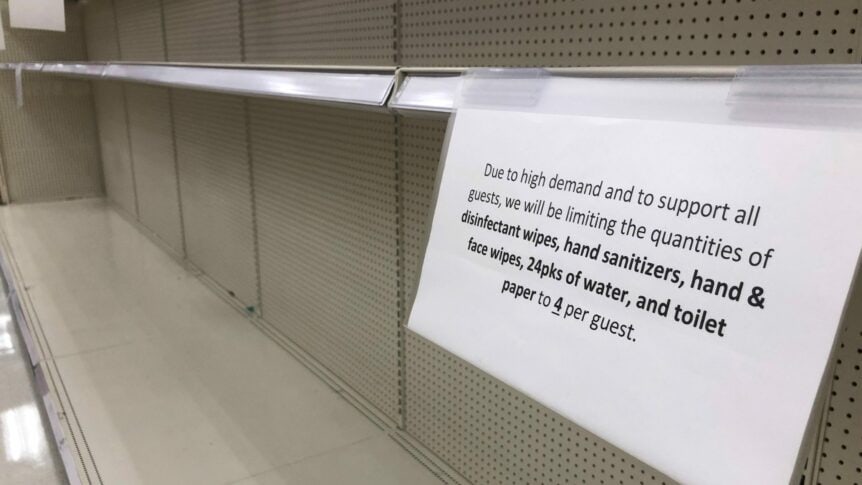

As we all try to adapt to a new lifestyle during the COVID-19 crisis, the amount of “hoarding” that is taking place is unprecedented and was not anticipated. When customers shift behaviors and start stocking up on the basics, it sends shock waves through the nation’s supply chain. Never in history have we experienced such an increase in demand; the supply chain cannot keep up.

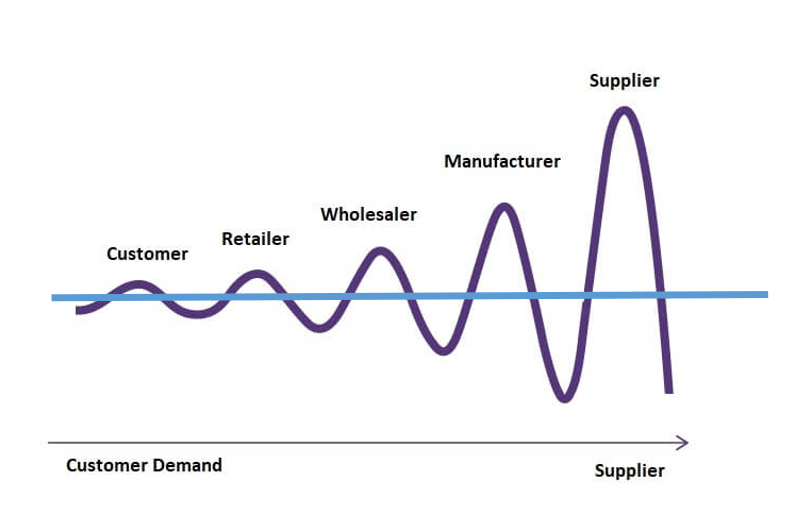

To put things in perspective, supply chain professionals have been able to anticipate increased demand due to hurricanes, earthquakes, and other natural disasters. Models have always been built in from the standpoint of the supply chain to accommodate for the hurricane season. The bullwhip – where the demand is extremely exaggerated even though there are no supply issues – occurs in every business and industry. We have been able to manage the overall impact on the supply chain. Figure 1 below shows how the bullwhip occurs.

FIGURE 1

You can see that the customer can “whip” the supply chain by the purchasing pattern. Supply Chain professionals have been able to deal with this pretty normal bullwhip by managing the supply to flatten the curve.

The perfect supply chain would be a flat line as indicated by the blue line above. This is normal behavior where supply chain professionals can manage the impact of such variability in demand.

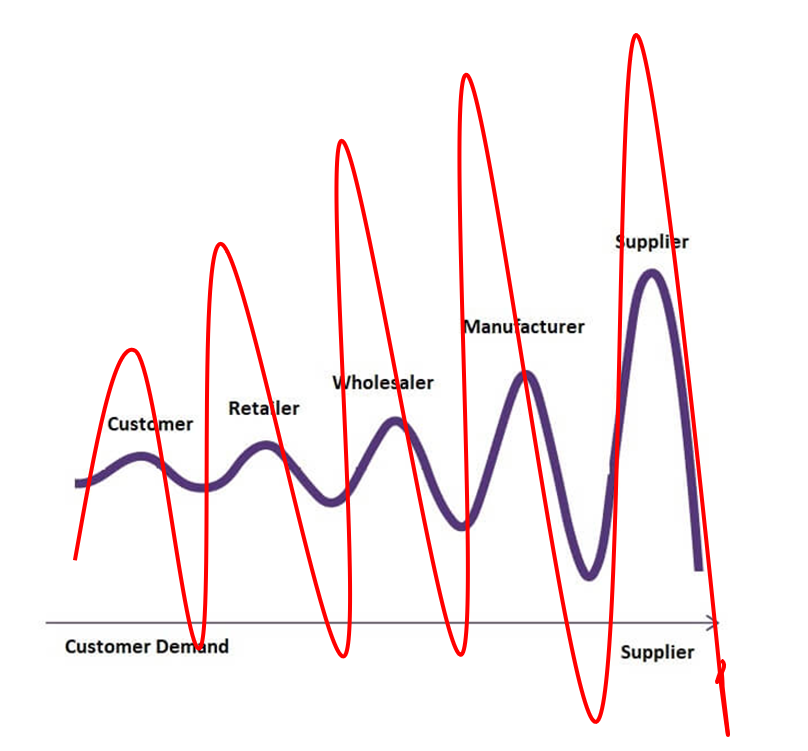

FIGURE 2

FIGURE 2

However, the impact of consumer behavior during the COVID-19 crisis is depicted above in Figure 2. The red line shows the dramatic bullwhip caused by “fear” and anticipation that supply will run out.

To return to the flattened line as shown in Figure 1, we must do two things:

- Ship supply as frequently as it is done in the normal bullwhip behavior.

- Control demand by putting restrictions on the amount that each consumer can purchase.

By doing these two things, the supply chain will become less strained. It mostly starts with us, the customers. We overwhelm our local store when we buy four times more toilet paper than normal, which overwhelms the distributor and manufacturer and supplier. To prevent this, we must control the demand by putting limits on the purchase. The logistics network will be less stressed and the supply will flow more fluidly as a result.

The bottom line is this – we all need to slow down on the exaggerated buying and hoarding. There is no doubt you have plenty of toilet paper!

Authored by M. Dave Malenfant.

Dave Malenfant is a Director of Outreach & Partnerships, Center for Supply Chain Innovation, at Texas Christian University Neeley School of Business. He has more than 35 years of experience in driving change and performance improvement across the supply chain. He also serves as the Executive Vice President of Industry Liaison and Talent Development for the Biotech Supply Management Alliance.